Moving, in sync, with the Industrial Revolution

The world today is in the phase of Industrial Revolution 4.0, which came with the advancements of digitalisation, robotics and artificial intelligence. Industry 4.0 has become more than just a namesake term. It is estimated that the introduction of IoT and AI will bring about a 30% increase in productivity, along with a cost savings of more than $200 billion, across different sectors.

In tandem with this culture, the textile industry underwent its own stage-wise metamorphosis. The first textile revolution was with the invention of the weaving loom. Textile 2.0 was the introduction of electrical energy and assembly lines, which led to the possibility of mass production of textiles. Textile 3.0 was the era of computerisation and electronics. At present, the advent of Industrial IoT, cyber-physical systems (CPS) and nanotechnology is considered as the onset of Textile 4.0.

The global textile market is in the exploring stages of advanced processes and smarter technology systems. Augmented reality, predictive maintenance, big data analysis, 3D printing and virtual reality are being extensively used in the manufacturing, logistics and sales of various textile sectors. Some of the noteworthy changes which have become a regular practice in the industry are:

- Transformation of manual labour to robotic systems, especially in cutting and dyeing process, to

produce precise and uniform results in mass production.

- Utilisation of RFID tags and QR codes to maintain documentation of each garment produced, useful

in its transportation, segregation, hoarding, etc.

- Real-time warehouse management and order tracking of shipments on both B2B and B2C level.

- Predictive maintenance of factories and machines.

- Introduction of augmented reality and virtual reality to explore market scenarios, training of

workforce and assistance in customer sales.

- Fully automatic, tamper-proof packaging for better storage and transportation.

- Real-time performance analysis of employees, supply chain and machinery.

- Use of sensors and advanced algorithms for quality- checks

It is being estimated that the introduction of AI and IoT in textiles manufacturing will reduce production costs by approximately 20% while saving time by more than 35% in processes. The major benefits which businesses can expect out of automation can be listed as follows:

Though the major benefits are listed, there are still many more that can be accounted for, due to IoT and automation. However, the transformation does come with its own set of challenges. This includes the initial investment in set-up, increased cyber risks, dependencies on the technically-sound workforce, absence of global standards and so on.

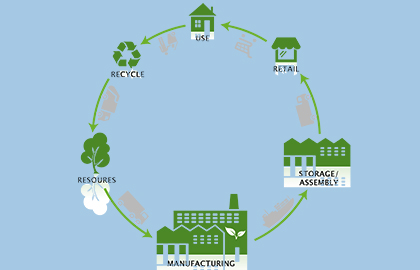

Moving forward, the textile industry will be experiencing a huge reformation. Some of the major aspects of Textile 4.0 will be innovation (in both - aterials and manufacturing), sustainability and eco-friendly practices. As the global markets shrink and become more accessible, it is hard to accurately predict the

true effects of this reformation to any certainty. What can be achieved in this phase of the textiles and apparels market is only a well-informed guess until the textile industry enters the phase of the next revolution.

In tandem with this culture, the textile industry underwent its own stage-wise metamorphosis. The first textile revolution was with the invention of the weaving loom. Textile 2.0 was the introduction of electrical energy and assembly lines, which led to the possibility of mass production of textiles. Textile 3.0 was the era of computerisation and electronics. At present, the advent of Industrial IoT, cyber-physical systems (CPS) and nanotechnology is considered as the onset of Textile 4.0.

TEXTILE 1.0

- Started in 1784

- Introduction of weaving loom and use of steam power.

TEXTILE 2.0

- Started in 1870

- Introduction of electrical energy and mass assembly lines

TEXTILE 3.0

- Started in 1969

- Beginning of

computerisation, automation and electronic systems.

TEXTILE 4.0

- Present Era

- Introduction of

Advanced Robotics, Machine Learning, Advanced Materials, IoT and so on

The global textile market is in the exploring stages of advanced processes and smarter technology systems. Augmented reality, predictive maintenance, big data analysis, 3D printing and virtual reality are being extensively used in the manufacturing, logistics and sales of various textile sectors. Some of the noteworthy changes which have become a regular practice in the industry are:

- Transformation of manual labour to robotic systems, especially in cutting and dyeing process, to

produce precise and uniform results in mass production.

- Utilisation of RFID tags and QR codes to maintain documentation of each garment produced, useful

in its transportation, segregation, hoarding, etc.

- Real-time warehouse management and order tracking of shipments on both B2B and B2C level.

- Predictive maintenance of factories and machines.

- Introduction of augmented reality and virtual reality to explore market scenarios, training of

workforce and assistance in customer sales.

- Fully automatic, tamper-proof packaging for better storage and transportation.

- Real-time performance analysis of employees, supply chain and machinery.

- Use of sensors and advanced algorithms for quality- checks

It is being estimated that the introduction of AI and IoT in textiles manufacturing will reduce production costs by approximately 20% while saving time by more than 35% in processes. The major benefits which businesses can expect out of automation can be listed as follows:

Safer working conditions

The best example of this is the implementation of safety measures and minimised manual intrusion while resuming work after the COVID pandemic scare.Increased efficiency

Better outputs through smart machine learning capabilities, data mining & analysis, calculated predictions, reduced wastage and so on.Cost-saving

Reduced skilled labour costs, operational costs, as well as faster processes and better work monitoring. An estimated reduction in the rejection rate of 50% is calculated within.Complete transparency

Digitalised data reduces mismanagement, manual errors and frauds.Increased customer satisfaction

Better quality products, faster response rates, transparency and reduced end-costs are a result of introducing automation, hence, leading to happier customersThough the major benefits are listed, there are still many more that can be accounted for, due to IoT and automation. However, the transformation does come with its own set of challenges. This includes the initial investment in set-up, increased cyber risks, dependencies on the technically-sound workforce, absence of global standards and so on.

Moving forward, the textile industry will be experiencing a huge reformation. Some of the major aspects of Textile 4.0 will be innovation (in both - aterials and manufacturing), sustainability and eco-friendly practices. As the global markets shrink and become more accessible, it is hard to accurately predict the

true effects of this reformation to any certainty. What can be achieved in this phase of the textiles and apparels market is only a well-informed guess until the textile industry enters the phase of the next revolution.